Technology and Knowledge Management

Importance and Mission

To achieve the company’s goal of becoming a sustainable organization amid business challenges and trends of energy transition which will impact the entire energy sector in the future, PTTEP attaches great importance to technology development and innovation, as well as knowledge management which are essential for business efficiency and competitiveness, ensuring the Company is well prepared for the future.

Goals

Develop and apply technology to support the organization's strategies in three areas: increasing operational efficiency and reducing costs in petroleum exploration and production, supporting the achievement of net zero greenhouse gas emissions by 2050, and enhancing competitiveness in low-carbon business operations.

Develop technology to support the Company’s sustainability which are Circular Model for E&P, as well as marine ecosystem preservation and restoration through Ocean for Life.

Put in place an effective intellectual property management system and register an intellectual property out of the research and technology development outcome yearly.

Publish research papers in international conferences and journals and win the prize for national and international innovation award competitions every year.

Enable the Company to increase the value of its intellectual capital (human capital, structural capital, and relational capital) and leverage its knowledge asset in order toto be recognized at international level.

MANAGEMENT APPROACH

Technology and Innovation Management

PTTEP Technological Development

PTTEP researches and develops technology and innovations to support the company's goals in sustainability, whereby PTTEP carries out research & development in new technologies through collaboration with domestic and international partners including companies in PTT Group, government agencies, private companies, academic and research institutions. PTTEP has three main objectives in technology development:

- 1 To increase operational efficiency and reduce costs in petroleum exploration and production.

- 2 To support the achievement of net zero greenhouse gas emission by 2050.

- 3 To enhance competitiveness in low-carbon business operations.

The following are details of technology development in 3 objectives.

Technology for increasing operational efficiency and reducing costs in petroleum exploration and production

PTTEP applies technologies in petroleum exploration and production to enhance petroleum production efficiency, reduce production costs and minimize environmental impact. Examples of technology that have been developed and implemented include the following:

1. Enhancing Petroleum Production Technology

Improving efficiency and resolving issues in the production process are crucial to increase production and lower unit costs. PTTEP has been developing technologies to continuously enhance production in various fields as follows:

- Condensate treatment: Various condensate treatment technologies have been developed to increase efficiency and reduce costs such as the adsorbent, liquid-liquid coalescer to separate the contaminant water from condensate and filter, the improvement of unwanted component measurement, etc.

- CO2 removal: PTTEP has developed technologies to increase the efficiency of Carbon Dioxide separation and reduce the loss of saleable gas, such as development of CO2 removal membrane technology, development of metal-organic framework (MOF) absorbents, etc.

- Produced water quality improvement: PTTEP has developed flocculating agent to accelerate the precipitation of contaminant in produced water.

2. Operational Efficiency Improvement Technology

Operations in the petroleum production process in an efficient way are beneficial in terms of increasing production, reducing costs, and increasing work safety. PTTEP has developed technologies to improve operations in many areas such as the development of autonomous robots to perform field operation activities and detection of equipment abnormalities on petroleum production platforms, and a diamond-like carbon coating to prevent process equipment from corrosion and erosion, etc.

3. Petroleum Facility and Installation Decommissioning Technology

In the petroleum production process, both onshore and offshore, various types of facilities and installations are involved, such as petroleum production platforms, petroleum pipelines, and production wells. When production ends, these installations must be decommissioned from the production area. Decommissioning is a costly process with potential environmental impacts. Therefore, PTTEP has been developing technology to support the decommissioning of these installations, including:

- Offshore petroleum pipeline decommissioning technology: PTTEP has developed innovative chemicals for decontamination (MERClean) and a sampling device for collecting samples from inside pipelines (MERIns) to support environmentally friendly pipeline decommissioning. The development of these innovations began in 2015 through collaboration with educational institutions, government research institutes, private sectors, and environmental experts. This collaboration successfully led to the development of these innovations. PTTEP is currently developing the efficiency and accuracy of the sampling devices.

- Petroleum well plug and abandonment technology: This technology uses high heat from the combustion of materials to melt metal, effectively sealing the production wells.

- Offshore installation post-decommissioning monitoring technology: This involves the development of devices for measuring and monitoring the condition of various installations to ensure they remain in suitable condition and do not impact the environment after decommissioning.

These technologies are new innovations that help reduce costs, increase safety in decommissioning operations, and minimize long-term environmental impacts.

Technology for supporting the achievement of net zero greenhouse gas emissions by 2050

The development and application of new technology is part of supporting the Company’s goal to achieve net zero greenhouse gas emissions by 2050. The research and development of various technologies have been carried out including technologies for reducing greenhouse gas emissions such as Carbon Capture, Utilization and Storage (CCUS), the development of low heating value flare tip, and the development of post-combustion carbon capture technology to reduce greenhouse gas emissions from machinery on petroleum production platforms. Additionally, there are technologies for generating electricity from renewable energy sources, such as wind turbines for electricity generation on wellhead platforms and the study of various renewable energy sources for electricity generation on offshore production platforms. Furthermore, there are also technologies for reducing greenhouse gas emissions through offsetting methods.

Technology for enhancing competitiveness in low-carbon business operations

Energy transition or the transition from fossil fuels to renewable energy or alternative energy that reduces Carbon Dioxide emissions is a change that directly affects PTTEP's business operations. As for technology development, PTTEP has prepared to support the Company's business to be ready for such changes by studying and developing hydrogen production, renewable energy generation such as wind energy, wave energy, geothermal energy, and new forms of energy. In addition, the Company also established the Green Energy Technology Playground in the area of PTTEP Technology and Innovation Research Center (PTIC) as an area for clean energy technology development, testing and extend the implementation of clean energy technology to real application.

In addition, PTTEP is committed to developing technologies that support the organization's sustainability in various areas, including Circular Model for E&P, and Ocean for Life. Examples include the project to develop technology for oil sand from petroleum production management to reduce environmental impact from waste disposal processes through landfill process, and the project to develop sensor technology for measuring microplastics quantity to help monitor and provide data for addressing microplastic issues in water sources.

Technology Development Management

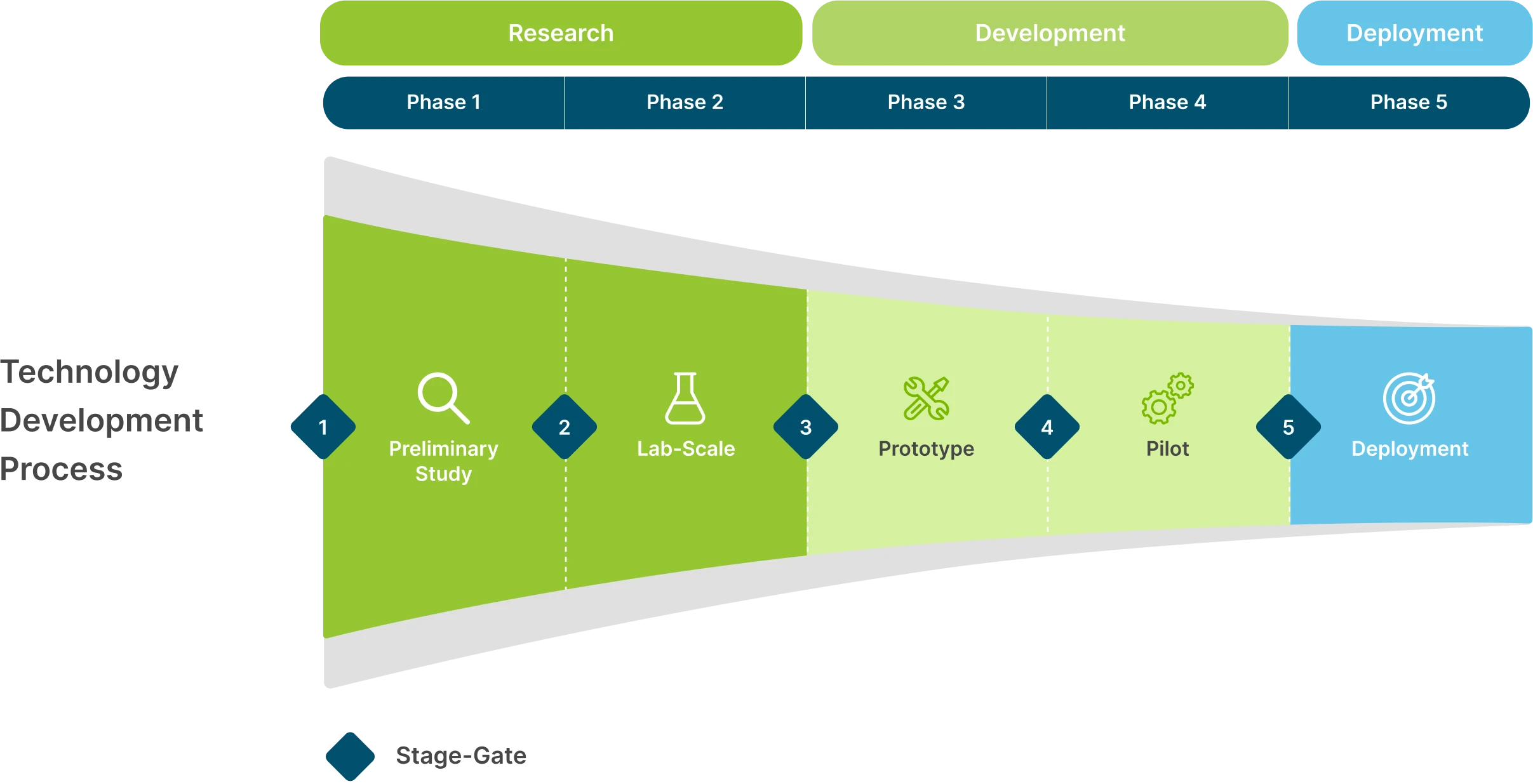

PTTEP has a technology management division specifically taking care of the management of the Company's technology development. Technology Development Process (TDP) is a framework for managing technology development for maximum efficiency. The process is divided into 5 phases of the technology development which are preliminary study, lab–scale testing, prototype development, pilot testing, and deployment or commercialization phase, which is aligned with the technology development at the international level, known as the Technology Readiness Level (TRL). The Technology Development Process is also a tool to assist in the selection and approval of projects, as well as to support the technology development project until it is successful and can be implemented or commercialized. The technology development is under supervision and advisory on overall management in accordance with the Company's direction and policy from the Technology Development Committee.

In addition, the Company has an Intellectual Property Management Process as a framework for systematic management and expert personnel to manage intellectual property works resulting from PTTEP's technological and innovation developments.

For more information on R&D budgets, the number of projects under R&D process, progress, patent registration, research papers and publications, and innovation awards, click here: Innovation and Technology Performance Data.

Infrastructure to Support Technology Development and Innovation

PTTEP has established PTTEP Technology and Innovation Center (PTIC) in the Eastern Economic Corridor of Innovation (EECi) at Wangchan Valley, Rayong Province. PTIC is equipped with modern facilities and equipment, including laboratories and operational rooms, 3D printing fabrication rooms, pilot area building for prototype testing, UAV test field for unmanned aerial vehicles, and green energy technology playground for studying, testing, and developing clean energy technologies such as solar power generation and new forms of energy like hydrogen power generation, fuel cell technology, and advanced energy storage technology.

PTIC will play a key role in enhancing PTTEP's competitiveness by driving and accelerating the success of technology development and innovation towards faster industrial application. PTIC also plays an important role in the development of technology personnel of the nation. It is an area for exchanging knowledge of researchers and experts and building a research network internationally to help extend and drive sustainable technology development.

In addition, the Company has established PTTEP Subsurface Research Center or PSRC at Hi-Tech Industrial Estate in Ayutthaya Province. This center is dedicated to support geological research and strengthen petroleum exploration and production capabilities, evolving from its beginning as the PTTEP Core Research Center (PCRC). PTTEP Rapid Scale-up Center (RASC) has also been established, located within the Map Ta Phut Industrial Estate in Rayong Province, to help accelerate scale-up and pilot use of technologies related to petroleum production. The center also supports technologies aimed at reducing CO2 emissions.

Knowledge Management

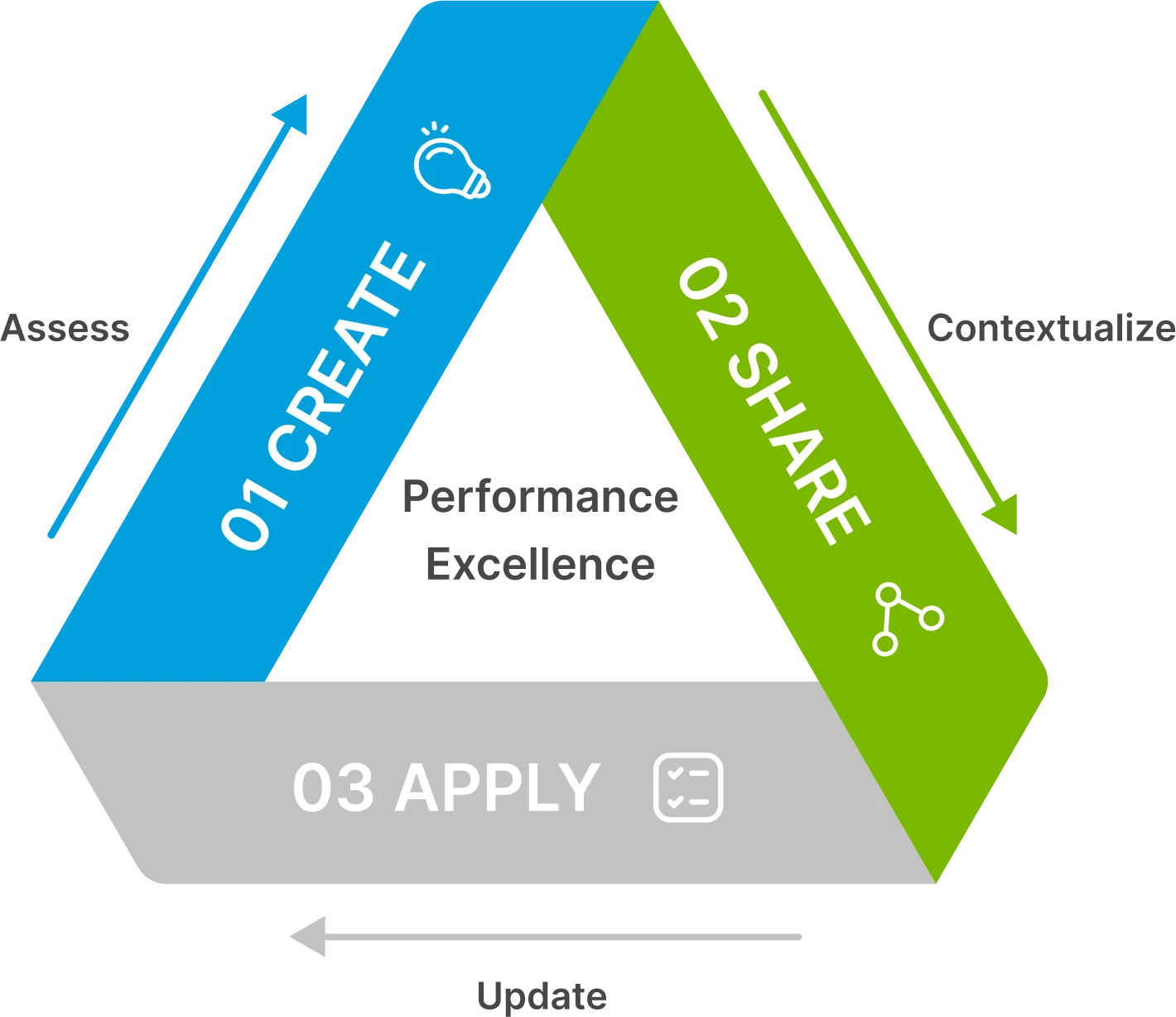

PTTEP's knowledge management (KM) entails 3 dimensions: Create, Share and Apply.

Employees are encouraged to seek previous lessons learned, study and adhere to guidelines, ensuring the correct and effective use of knowledge. Knowledge gained from experiences should be shared, and employees are expected to apply the learned knowledge before performing their duties, to reduce errors and enhance problem-solving skills. This process fosters the development of new work standards, ultimately leading to innovations.

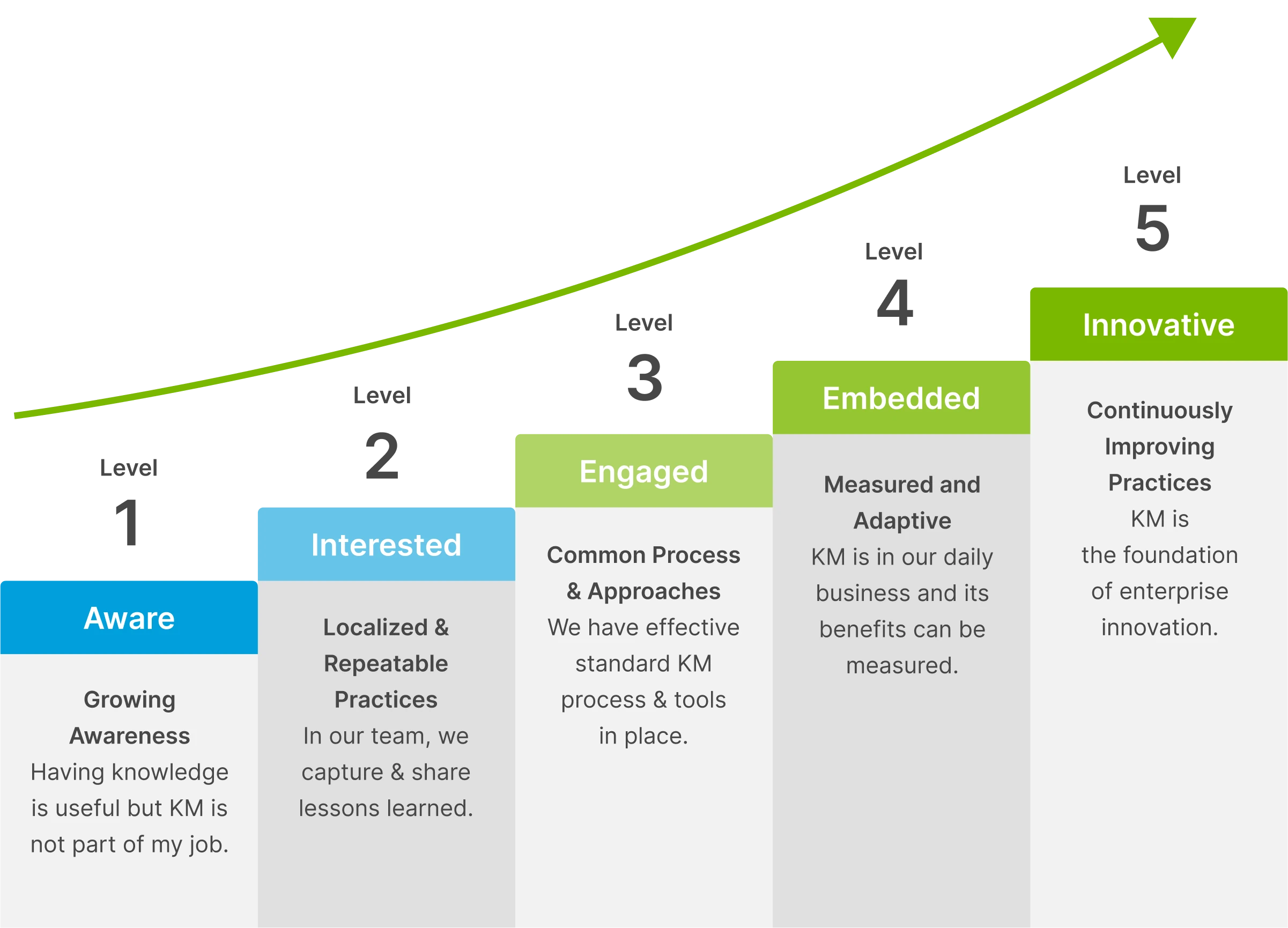

PTTEP aims to become an Innovative and a High-Performance Learning Organization where knowledge creating, sharing and applying are the way we work. Our KM policy is shaped to achieve this goal in alignment with PTT Group's KM policy. PTTEP's KM maturity is regularly assessed and benchmarked against international practices, to identify areas for improvement and develop strategies to embed KM into work processes, reinforcing the organization’s innovation-driven vision.

PTTEP focuses on 3 core KM strategies:

- 1 Delivering Business Values

- 2 Nurturing KM and Innovative Culture: Encouraging a knowledge sharing environment that fosters continuous improvement.

- 3 Enhancing PTTEP Visibility: Strengthening employee expertise to achieve national and international recognition

To support these strategies, PTTEP organizes various initiatives, including executives' talks on the direction and strategy, leadership role modelling, standardized KM systems, and knowledge-sharing sessions with internal and external experts, as well as encouraging staff to participate at international conferences as committee members and speakers. In addition, the establishment and growth of an online KM Community of Practice (CoP) serves as a platform for queries, knowledge exchange, and discussions. There is also an internal KM website where staff can upload and search for knowledge, lessons learned and best practices. PTTEP continues to cultivate a robust KM culture through the following key initiatives:

KM Capability Development

Staff’s competency is enhanced through induction, roadshow, training and e-learning to ensure staff awareness of the importance and understanding in knowledge management.

Critical Knowledge Identification and Knowledge Mapping

PTTEP identifies critical knowledge for both current and future operations. The Company manages its knowledge systematically based on the identified critical knowledge as well as seeking for knowledge essential for day–to–day operations as well as to support business growth.

Specialist Directory Development

The Company identifies experts based on the identified critical knowledge and develops a specialist directory for staff to easily access and search in the event they require support and recommendations.

Knowledge Capture Process from Projects / Experts / Retirees

The Company conducts a workshop after each project ends to capture lessons learned from operations. The lessons learned can be used for the next project to minimize mistakes that might occur and to increase operation effectiveness. The Company also captures knowledge and experiences from experts and retirees in various forms which are then posted on the KM website.

Human Library

The ‘Human Library Project’ is an integral part of the knowledge management activities with primary objective to support PTTEP’s vision and knowledge transfer. The Company identified 17 areas of expertise within PTTEP and selected ‘experts’ from Management and staff as Human Books for sharing their unique experiences, best practices and serve as a resource for creative problem-solving, allowing employees to consult and receive guidelines or tips. The value created by the Human Library Project significantly contributes to the essential skills and competency development of PTTEP’s employees as well as strengthening knowledge exchange within company, in line with our goal of being a Learning Organization. The Human Library session is held in a small group informal setting, which allows participants to engage in in-depth discussion, ask questions and gain insights.

Corporate Knowledge Sharing

The corporate knowledge sharing sessions are one of the major activities in KM, where all staff can attend due to the less technical content being suited to a wider audience, and covers a wide range of topics, technical and non-technical, with speakers from within the company as well as some external speakers. They are held onsite and online to reach as many people as possible, as well as being recorded and uploaded onto the KM website for future reference. In addition, site visits to leading companies are arranged to allow staff to learn and broaden their knowledge outside of their line of work.

IT System Enhancement

The Company develops and continually upgrades the KM website as a central hub for searching and sharing various forms of knowledge, incorporating AI to improve the search function. There is also an online application (Viva Engage) which contributes to the rapid growth and active contributions and discussions of our KM community.

Nurturing KM culture and Recognition through KM Award and Recognition

PTTEP launched the ‘Recognition’ program, to praise individual employees or teams whose contributions support the Company’s 3-step knowledge management cycle: Create, Share and Apply. The Individual Awards celebrate outstanding contributors in three categories Best Expert, Best Contributor and Best Learner. In addition, the Community of Practice (CoP) Award recognizes CoPs that drive collaboration, innovation and knowledge sharing.

The annual KM Week event consisting of the 28th Technical Forum and 6th Business Forum was held. The forums which attracted 259 technical paper submissions, as well as posters and exhibitions, allow the employees to present their work with Awards given out for the best papers, and posters.

Organization-wide communication

PTTEP prepares a year-long communication plan, to ensure correct understanding in the organization’s knowledge management and provide information on KM tools. Personnel can therefore appropriately utilize these tools for the betterment of their operations and their daily life.

PTTEP adopts a process that promotes the exchange of knowledge, experiences, and best practices with American Productivity & Quality Center (APQC). APQC's knowledge management capability assessment put PTTEP in Level 5 in 2022 (the highest level). The assessment results are reviewed for further improvement, so that knowledge management can support the Company's vision and mission in achieving the stated targets for sustainable growth. PTTEP also receives Gold Level of Southeast Asia Most Innovative Knowledge Enterprise (SEA MIKE) Award since 2021 for four consecutive years. In addition, PTTEP receives the Global MIKE Award which is granted to enterprises that demonstrate world-class innovation and knowledge management for four consecutive years.