Supply Chain Management

Importance and Mission

The oil and gas industry operates in just about every imaginable geographic and climatic conditions across the world. Managing complex supply chain is a success factor to ensure effective management of the flow of product or service including on-time delivery of people, materials and equipment to operational sites. In addition, to support EP Net Zero 2050 target.

Supply Chain Management will not only contain possible risks on the operations and corporate reputation but also increase operational efficiency, transparency, and shared values between PTTEP and suppliers. Such management as guided by the principles of cost-effectiveness, transparency, efficiency, effectiveness, and traceability involves the first step in selecting vendors and suppliers. It entails a review on suppliers' management of environmental, social, and governance risks (ESG risks), relationship building, and suppliers' capability enhancement through the adoption of digital technology.

Goals

Zero Incident Organization

PTTEP is committed to Safety, Security, Health and Environment (SSHE) management to achieve zero incident organization target. The goal encompasses major accident events, oil and chemical spillage, motor vehicle incidents, marine vessel incidents, total recordable injury and loss time injury, to ensure nobody gets hurt and everybody returns home safely. More information is available in the SSHE Policy.

Green Supply Chain

PTTEP implemented Green Supply Chain in 2019 through the green procurement of goods and services and the development of energy-efficient logistics, in order to reduce greenhouse gas emissions from combustion which causes global warming.

Local Content

PTTEP supports local businesses and encourages the procurement of goods and services in the operating areas, to support local economy, employment and income distribution, resulting in PTTEP having a good relationship and gaining acceptance in the countries where PTTEP operates. Moreover, PTTEP encourages suppliers to operate with responsibility and to source products and services in local areas.

Supplier Management and Vendor Sustainable Code of Conduct

PTTEP sources goods and services with honesty, integrity and fairness as guided by the Company's governance principles. The Company takes into account environmental impacts; economic and social factors; contract terms and conditions; pricing; quality; delivery; and SSHE requirements. On top of that, contractors must comply with all of the principles and give importance to social responsibility.

PTTEP believes that it is vital to conduct business under Good Corporate Governance and Business Ethics and emphasizes the rights of internal and external stakeholders' rights through the Supply Chain Management Policy and related activities. For example, PTTEP joins the Integrity Pact (IP) to strengthen the national fight against corruption in line with the procurement and anti-corruption laws. PTTEP is also a member of Thailand's Private Sector Collective Action Coalition Against Corruption (CAC).

Cost Effectiveness

The Supply Chain Management Policy to source quality goods and services at the best prices and at the best time is consistent with PTTEP's objectives, ethics and policies as well as relevant laws. PTTEP has adopted more digital procurement systems which have further lowered expenses but raised efficiency.

PTTEP also resorts to PTT Group's integrated procurement scheme for selected goods and services, in order to increase leverage and synergy across the petroleum supply chain. Such goods and services are, for instance, air filter for gas turbines, spare part filters, turbine compressor maintenance services, and procurement of life insurance for PTT Group's personnel.

Management Approach

PTTEP's Supply Chain Management Policy focuses on the efficiency in preventing and reducing social and environmental risks and the monitoring of suppliers that may affect stakeholders' trust in PTTEP's operation and consequently affect the overall business. Under the policy, the procurement of local goods and services is encouraged to support the local economy and generate income where PTTEP operates.

Governance

The PTTEP Supply Chain Governance is structured to ensure efficient, compliant, and strategic management of the supply chain. The Supply Chain Management Division, plays a crucial role in the governance and strategic management of the company's supply chain. Positioned under the Operations Support Group, the division ensures that all policies, standards, and systems are aligned with pertinent regulations and company objectives. Notably, the Supply Chain Management Division reports up through the Operations Support Group to the Chief Executive Officer (CEO), ultimately ensuring that all supply chain activities are aligned with the executive leadership's vision and strategy. This structure facilitates direct reporting to the Board of Directors through the CEO, integrating supply chain operations tightly with the company's overarching goals. The Corporate Governance and Sustainability Committee (CGSC) oversees the sustainability strategy, framework, and sustainability materiality issues, including Supply Chain Management. The implementation of sustainable supply chain and ESG-related practices, such as ESG supplier assessments and supplier ESG programs is also under the oversight of CGSC. (More information in Sustainability Framework and Long-term Target and Sustainability Governance Structure.) This alignment is crucial for maintaining operational efficiency and compliance on a global scale within PTTEP.

Vendor Management and Vendor Sustainable Code of Conduct

Under the commitment towards sustainable development and the development of local communities and the environment, PTTEP gives importance to supply chain management and the implementation of those rules on vendors. PTTEP Vendor Sustainable Code of Conduct was formulated, which covers relevant rules, regulations and laws. Such code is aimed at enhancing vendors' knowledge and understanding in sustainable development and ensuring that their operations integrate ethics, respect to human rights, occupational health and safety, and environmental management.

Quality, Transparent and Accountable Procurement

PTTEP encourages the bidding for our procurement process. This practice not only allows qualified and capable suppliers an opportunity to offer their product and services but also reduces the cost. Through bidding, suppliers can be controlled and evaluated against the preset standards and terms as well as the Company's policies on corruption and Safety, Security, Health and Environment (SSHE) standards. (Procurement data is shown in the Supply Chain Performance Data. )

Key Aspects of Sustainable Procurement Process

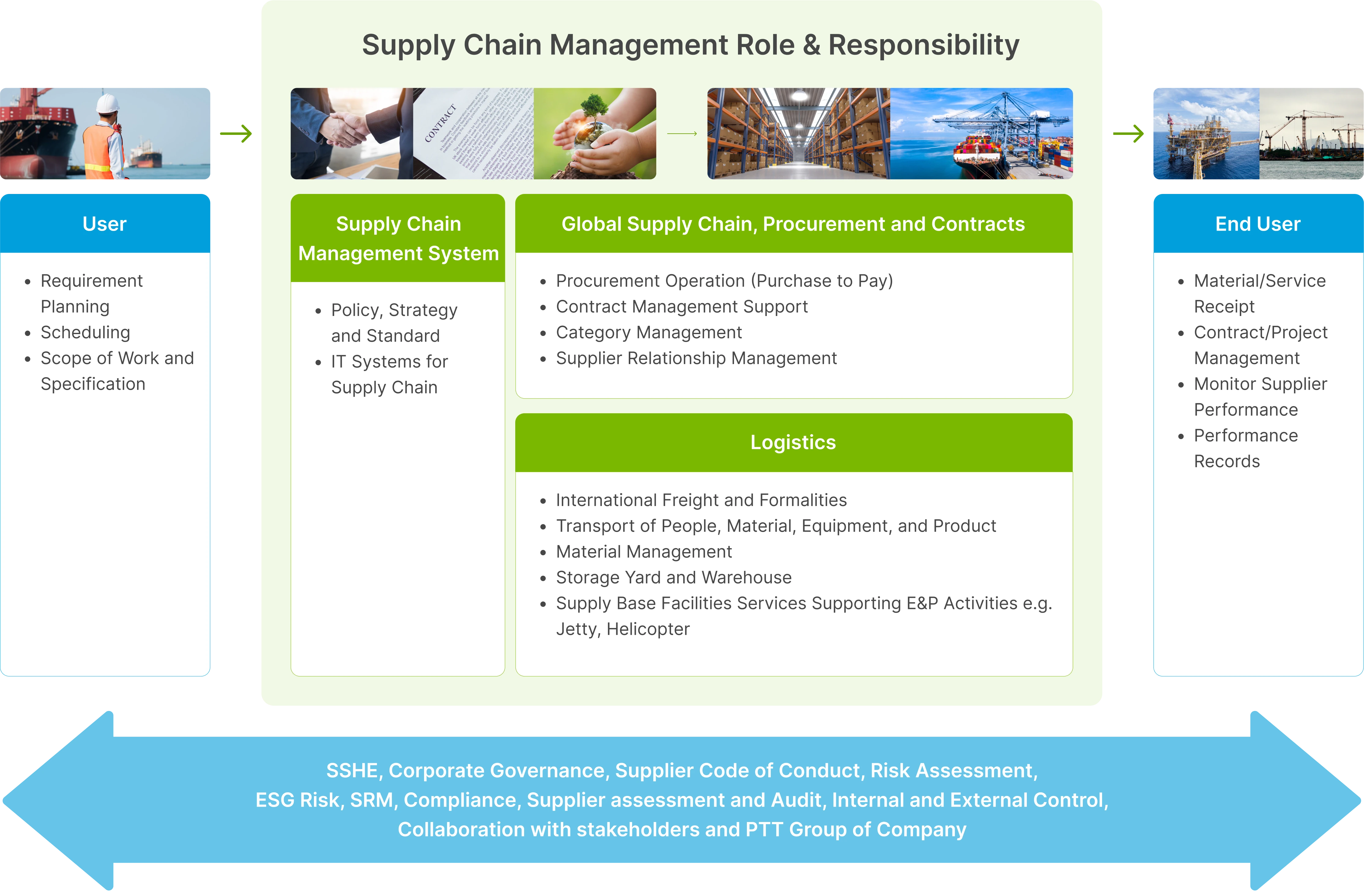

PTTEP Supply Chain Management (SCM) Model

Below is PTTEP's Supply Chain Management model with illustration of key activities, roles, as well as supply chain management processes to facilitate all petroleum exploration and production activities in an integrated manner.

Supply Chain Management Principles

PTTEP's Supply Chain Management principles consist of four main elements as follows:

Supply Chain Management System

Supply chain management strategies, Procurement and Contracts

Logistics

Petroleum Development Support Base

Supplier Selection and Retention

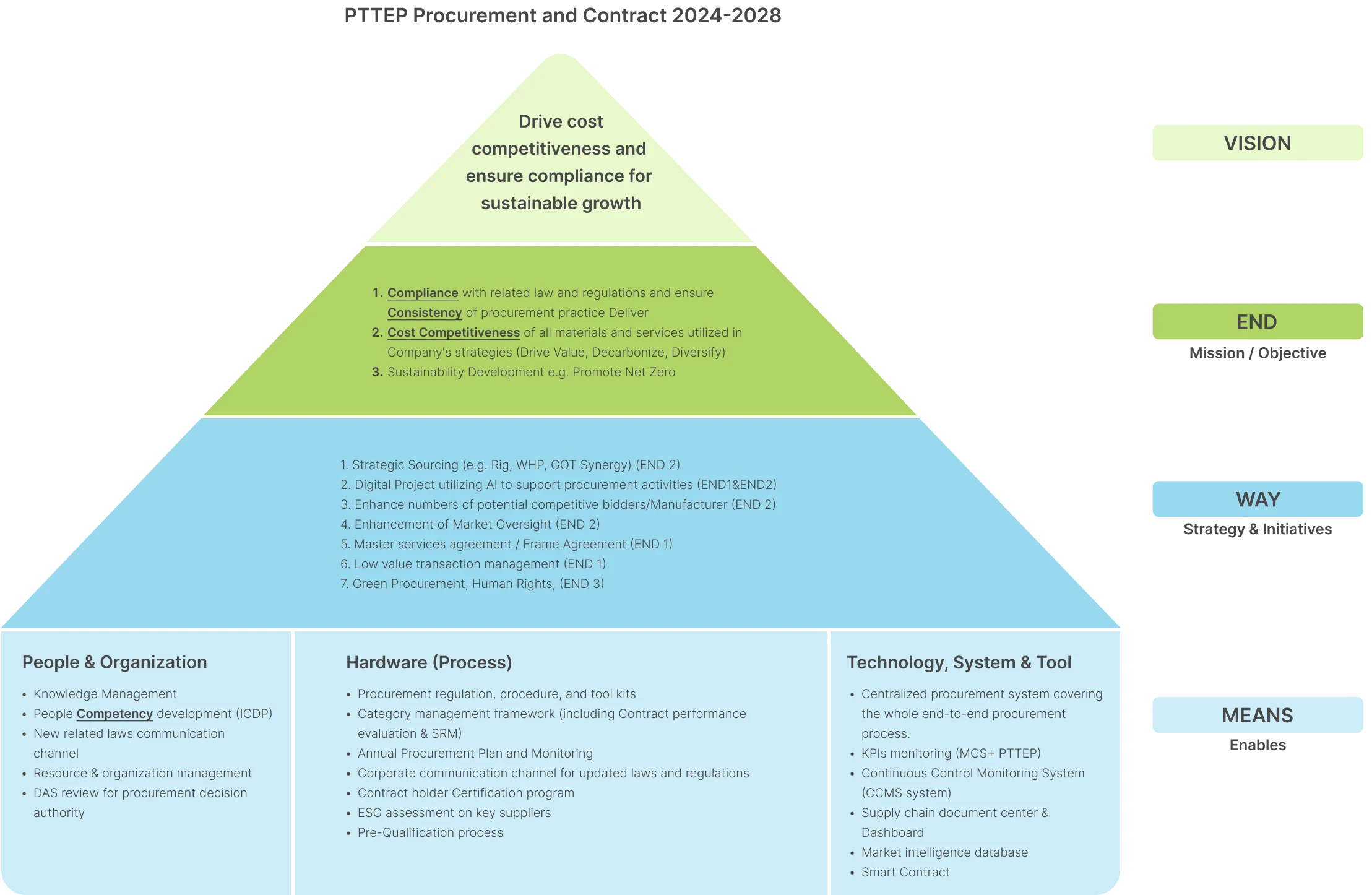

Procurement and Contract Strategy

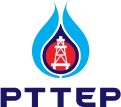

The framework and strategy for procurement and contracts, as shown below, is to align long-term targets with the Company's business objectives and direction. It also guides the procurement unit on the execution of activities, to achieve the targets in a sustainable manner.

To integrate ESG considerations into supply chain, PTTEP includes clauses in its general procurement terms and conditions for procurement to address business ethics, safety, security, health and the environment to require suppliers and contractors to conduct their business in conformance with the laws and PTTEP's requirements of Safety, Security, Health and Environment Management System (SSHE MS) and the company's business ethics as in alignment with Supplier Code of Conduct and to avoid potential conflicts with ESG requirements. PTTEP’s pre-qualification assessment covers ESG aspects to select appropriate suppliers/vendors; it prioritizes the level of enforcement and engagement with suppliers/ vendors. PTTEP has included % (weight) of ESG assessment in the Pre-qualification process. Suppliers who will be participating in any of the project categories for tendering/bidding with the contract value of USD 1 million and above. The company will apply 100% screening and evaluating vendors according to their business categories.

The evaluation process is done consisting of the following sections: 1. Technical and Quality section 2. Safety, Security, Occupational Health and Environmental (SSHE) section 3. Commercial, Legal and Social section to ensure that the vendor has the qualification to participate in PTTEP’s work. This means that if vendors fail one out of three sections above then, they will not pass the pre-qualification process altogether. As a result, suppliers are excluded from contracting if they cannot achieve minimum ESG requirements. The evaluation is based on fairness, equality, and transparency for the highest benefit to PTTEP where suppliers with better ESG performance are preferred in supplier selection and contract awarding.

The implementation of such supplier ESG programs are overseen by Executive Management. The key elements are as follows:

Risk Assessment

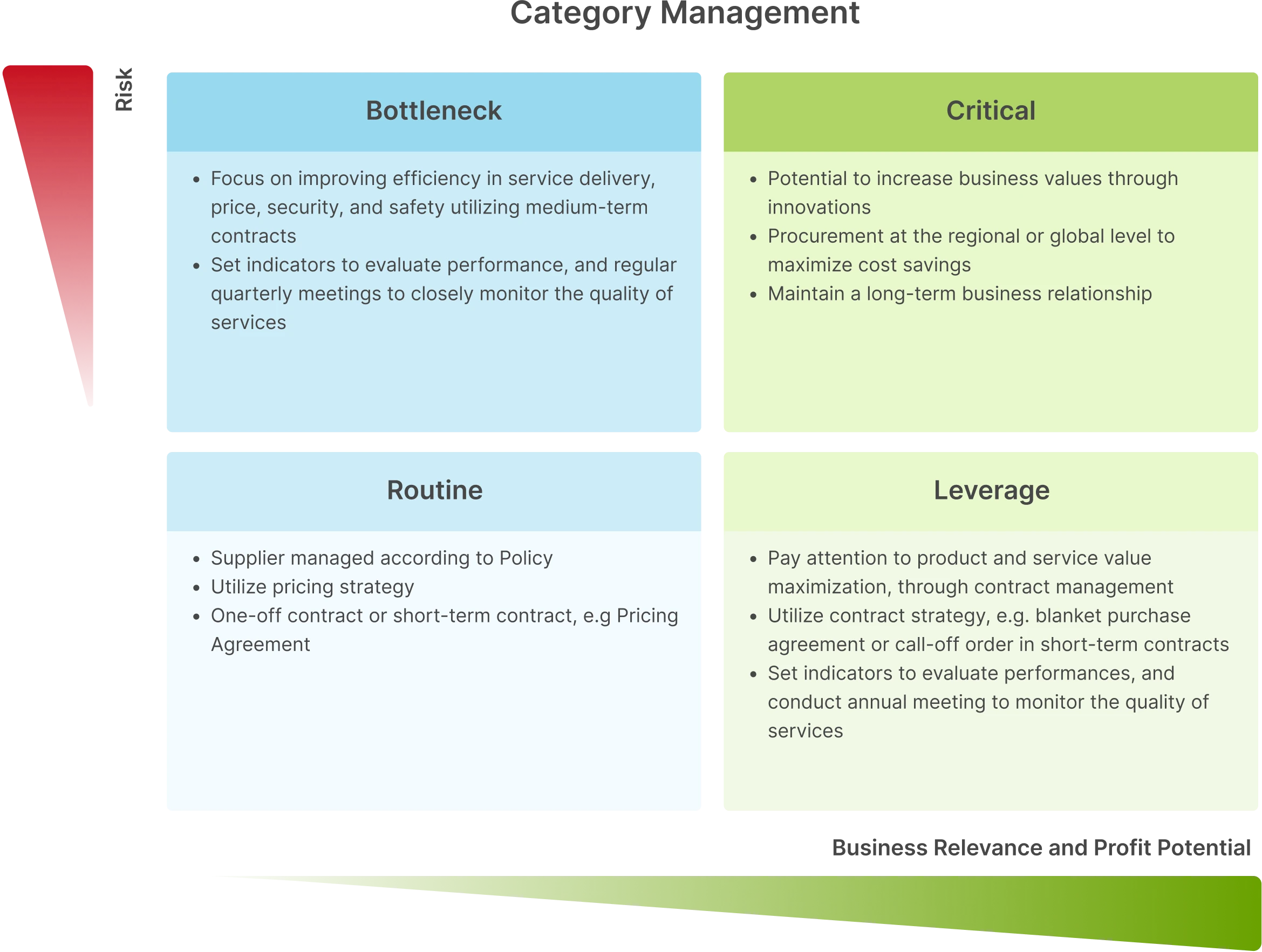

Risk Exposure by Category Management

PTTEP identifies significant suppliers by conducting work category analysis to classify & prioritize work categories, then select significant suppliers from important and high-priority work categories from their spending volume and risks (e.g. providing of significant component or non-substitutable supplier). PTTEP uses Supplier Positioning Model (SPM) as tools to identify and analyses relationship between “Risk” and “Profit Potential” in which can be described as followed:

"Risk" associates with

a. Sustainability (Environmental, Social, Governance - ESG) and technical risk during operation including supplier who provide significant component.

Sustainability and Technical Risk that arising during operations. Safety and environmental and reputation impact risks are also taken into consideration apart from technical risks such as financial, design maturity, manufacturing/service complexity, and legal/non-compliance impact. The weight of Sustainability and Technical Risk is accounted for 34% of total risk.

b. Supply risks, non-availability or failure of supplied materials and services.

Supply Risk arising from the vulnerability of the business to the unreliability of the supply market at the acquisition stage of the procurement process. Criteria for consideration include company’s experience with product/ service, delivery performance, geographical distance, potential suppliers, non-substitutable supplier, and degree of market saturation. The weight of Supply Risk is accounted for 66% of total risk.

"Business Relevance and Profit Potential"

is the degree of opportunity, which exists for the procurement process to contribute to Company’s profitability. Criteria for consideration to determine the level of Profit Potential include, for example, company’s annual spending (high volume spending) and degree of opportunities that reflect in terms of potential suppliers, price elasticity, degree of market saturation.

SPM is divided into 4 categories: Critical, Bottleneck, Leverage and Routine. Significant/ critical suppliers are suppliers who have high profit potential (annual spending value above 1 MMUSD) and pose high technical and supply risk and categorized in Significant/ Critical, Bottleneck, Leverage quadrants of the SPM model. While critical suppliers are suppliers who pose a very high or high risk and were categorized as high-risk tier 1 suppliers.

Category Management system is also the basis of Supplier Relationship Management, in terms of supplier categorization, as well as the improvement in procurement process for better alignment with product and service categories. Total procurement values from direct suppliers within Thailand and Overseas shown in Supply Chain Performance Data. )

Assessment of Supply Chain Management Risks

Supplier Risk Assessment

Suppliers are one of the key stakeholders to help drive the business towards sustainability. PTTEP thus applies the following 5 steps to assess suppliers' risks to avoid and reduce ESG-related risks:

1.1

New vendor pre-qualification by screening and evaluation of vendors accordingly to product and business category, size and geographical location and the type of work performed.

1.2

Spend analysis and risk assessment (Sector-specific risk, Commodity-specific risk) through Supply Positioning Model (SPM)

1.3

Assessment of suppliers' sustainability-related including environmental, social, governance and business risks

1.4

Integration of sustainability aspects in selection process and contract management

1.5

Supplier risk management

Supplier Risk Screening

Operation and SSHE/ Sustainability Management Risks

- Health impact

- Environmental impact

- Legal/ non-compliance impact

- Reputation impact

- Business and financial impact

Competitive Risks

- Market concentration (country, sector and commodity specific risk)

- Supplier view towards PTTEP

- Importance of business line (sector and commodity specific risk)

- Supplier profit level

Spending Risks

- Spending

- Maintenance cost

- Operating cost

- Obsolescence cost

- Disposal cost

Significant suppliers are Tier 1 suppliers that pose high risks in terms of business stability, expertise and supply risk. Such suppliers include those in the drilling operations and wellhead platform construction business.

Supplier/ Contractor Audit

PTTEP sets in place the supplier assessment desk with systematic verification of evidence and audit programs (on-site assessments) and implemented it during and after the contract period, to assess risks and ensure job completion. PTTEP also sets a plan to monitor corrections during and after the work and works with suppliers in executing corrective actions. Should economic, social and environmental risk occur, PTTEP and suppliers jointly locate the cause and find solutions. Corrective actions will then be jointly examined, taking into consideration the quality, quantity and safety in exploration and production. In addition, PTTEP also provides reporting channels in case of non-compliance thru whistleblowing helpline, if relevant to supply or contractor management this will be communicated to suppliers/contractors by PTTEP procurement.

SSHE Management System for Suppliers and Contractors

PTTEP has developed the SSHE Management System (SSHE MS) for suppliers and contractors as guidance for controlling and managing their operations. The system includes the following elements:

- Integration of SSHE screening criteria to procurement procedures

- Identification and assessment of suppliers and contractors' SSHE-related risks; and specification of SSHE responsibilities, control and operational approach, and the scheduled reporting of the contractors' SSHE performance.

- Development of initiatives to improve contractors' SSHE performance, such as a performance assessment system, training on SSHE to suppliers and contractors whose tasks involve specific risks, and an SSHE suggestion system for contractors.

- Communication of SSHE expectations to suppliers and contractors through various channels in order to cultivate awareness, performance improvement and preparation to satisfy PTTEP's demands.

- Support to suppliers and contractors' SSHE performance improvement to meet PTTEP's expectations.

SSHE Contractor Audit

PTTEP conducted SSHE audits on contractors who were awarded high-risk jobs, accordingly to PTTEP SSHE Contractor Management Standard and Procedure. The objectives are to ensure that the contractors understand and comply with legislations and PTTEP SSHE Management System, for efficient evaluation of risk management and efficient operations.

Subjecting to the annual SSHE Contractor Audit are the jobs that pose high risks relating to security, safety, health and environment such as drilling, construction, maintenance, logistics (land, sea and air), and past performance evaluation results. New contractors are also subjected to the audit.

The process to select contractors for the audit also depends on the contractors' SSHE records. Any contractors for high-risk jobs who are very likely to cause accidents, the Company will run the audit to improve their efficiency and safety and monitor the implementation of recommended corrective actions.

Environment, Social and Governance (ESG) Audit

PTTEP conducts an assessment on suppliers' sustainability on ESG aspect (ESG on-site audit), to assess sustainability risks in five areas: 1) corporate policy 2) business ethics 3) society 4) occupational health and safety and 5) environment, The assessment was done through a certified third party, to ensure that suppliers' ESG risks are audited and managed with the best practice. (ESG audit on contractors' data is shown in the Supply Chain Performance Data. )

Green Supply Chain

Green procurement is a component of Supply Chain Management. PTTEP Green Procurement Roadmap was initiated. Under PTTEP Green Procurement Roadmap (2016-2030), green procurement criteria for each function have been formulated since 2017 and appraised by the Thai Environment Institute (TEI). (Green procurement values are shown in the Supply Chain Performance Data. )

Local Content

PTTEP supports local products and services to promote the local economy. (Local refers to the country where PTTEP operates.) Particular emphasis is given to local suppliers with the capability of applying various innovations in developing goods and services accordingly to PTTEP's standards and requirements. Such development process is supported by information exchange as well as recommendations on work process improvement and safety issues, issued at meetings to follow up on suppliers' progress (Local procurement data is shown in the Supply Chain Performance Data. )

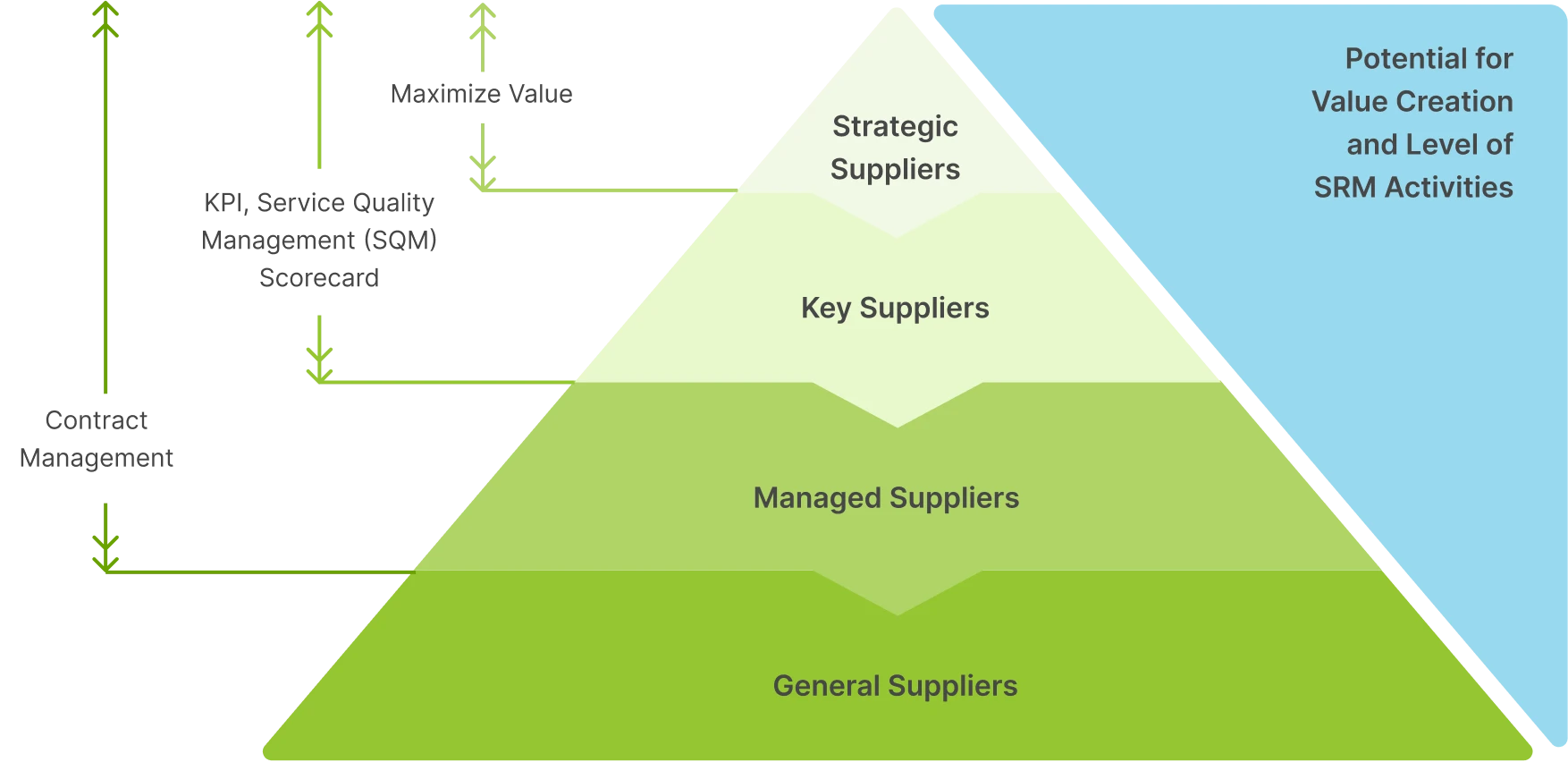

Cultivation of Good Relationship with Suppliers

PTTEP have enhanced relationship with suppliers through cooperation and the improvement in supply chain management efficiency. Strategic meetings are organized under the vision of "Energy Partner of Choice", to hear their suggestions and cultivate the understanding of both sides' operations, visions and technology strategies which will improve operational efficiency and foster true cooperation. Additionally, PTTEP also cooperated with key suppliers, such as those in drilling and production site management group, to create Master Service Agreement (MSA) in advance to establish contracts standards and relevant conditions for mutual benefits and operational efficiency.

Capacity Building and Training for Procurement Staff

PTTEP conducts capacity building programs to build capacity and improve ESG performances which includes training for company’s buyer and/or internal stakeholders on vendor ESG assessment program.

In PTTEP, all procurement staff can access supplier’s database where ESG factors are included in vendor assessment process. Procurement staff can access those data through Vendor Management System.

Reporting

PTTEP rigorously tracks and reports the extent and advancement of its supplier assessment and development programs. This process involves regularly evaluating suppliers against specific performance metrics and Key Performance Indicators (KPIs) to ensure compliance with PTTEP’s operational standards and sustainability objectives.

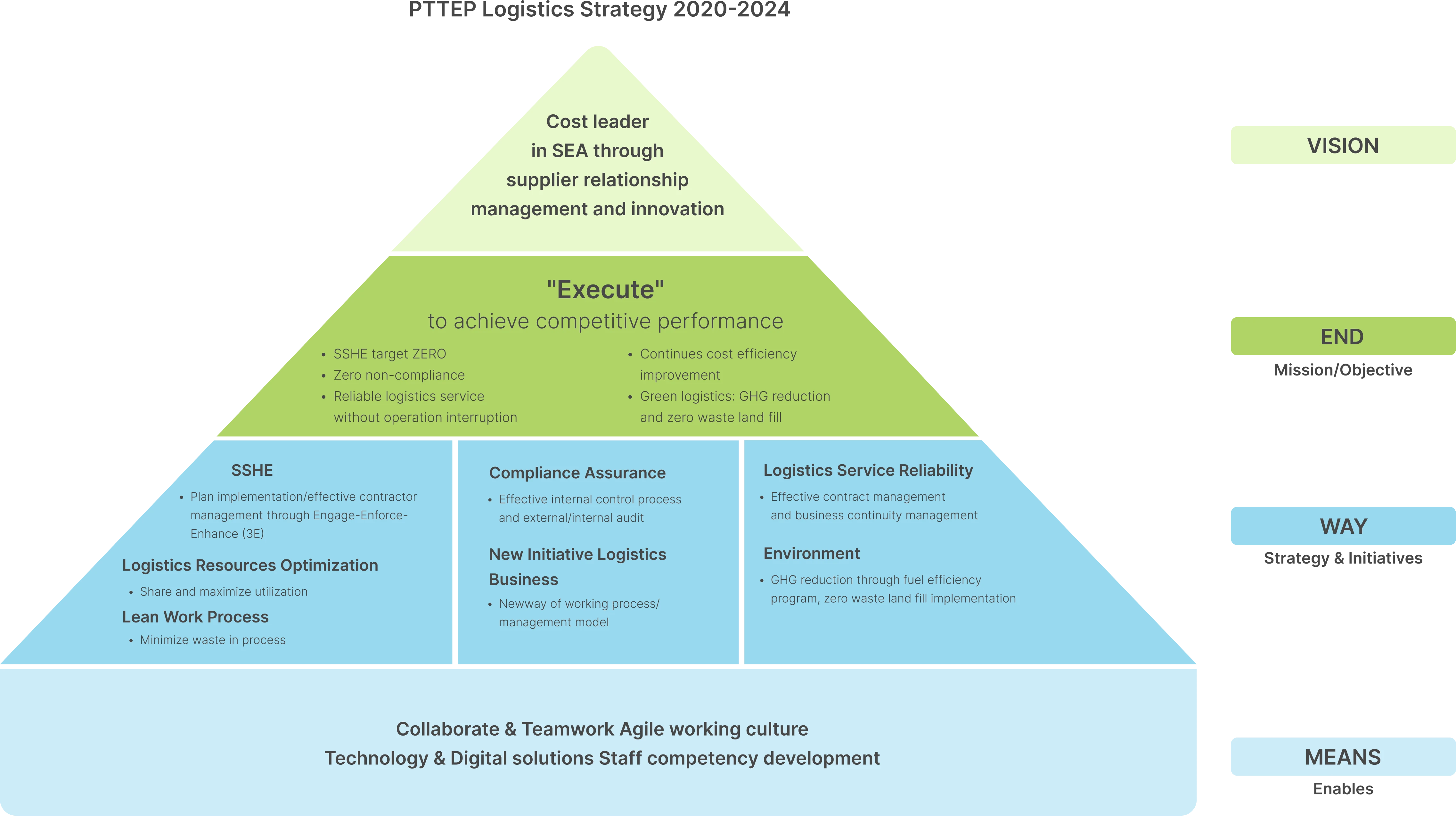

Logistics and Petroleum Development Support Base's Operational Strategies

The framework and strategy for logistics, as shown below, defines long-term targets in alignment with the Company's business objectives and direction. It also guides the planning on logistics operations and activities, to lead the Company towards the objectives in a sustainable manner.

SSHE Management

The Logistics Department considers SSHE a key aspect in business operations and is committed to preventing accidents by proactively promoting a culture of safety, security, occupational health and environment so that employees and contractors are aware of safety in their operations and comply with the standards that PTTEP expects. In addition, it is committed to preventing impacts on stakeholders and the environment through continuous activities such as:

- "Safety Stand Down" was organized at all operating areas to emphasize the importance of workers and contractors' safety and to enable greater safety and maximum efficiency.

- “PTTEP SSHE Forum” event to provide insights into safety and environmental awareness and expectations. In the event organized to discuss safety management concepts by PTTEP’s executives. Including making a joint commitment between PTTEP and business partners present the “SSHE Excellence Award” to contractor companies whose SSHE performance achieves PTTEP's targets.

- Driver's Fatigue Detection System was implemented to monitor driver behaviors including fatigue, drowsiness, loss of concentration, and negligence. This system incorporates Facial Recognition technology and Video Analytics to monitor real-time behavior via camera installed in front of the vehicle. While in transit, the camera monitors the driver and records data. High risks will trigger a sound and vibrating signal to the driver's seat and notifies the central control room for further action. The control manager is able to assess and evaluate the driver's long-term performance through the information dashboard shown in the data analysis system, to prevent possible risks and find measures that will improve drivers' training.

Inventory Management

Under the policy to keep inventory at an appropriate level, PTTEP enhances inventory management efficiency, particularly for the Bongkot, Arthit and S1 projects where held high inventory volume. Key points of such actions are:

Review inventory management

to ensure the design process, features identification, procurement, storage, disbursement and amortization is efficiently implemented and aligned with the Company's internal control measures as well as relevant government regulations. In 2021, PTTEP had executed pilot project to hand pipe products, parts of Oil Country Tubular Goods (OCTG) which contain high inventory value. To utilize the pipes efficiently for maximum benefits, the Company struck consignment contracts with a supplier, having the supplier store pipes at a central storage facility in Thailand for further distribution to all PTTEP projects. Each project will place orders accordingly to what it actually needs. The approach reduces pipes in inventory and facilitates the supply of pipes. The Company also improved the pipe procurement strategies, by sourcing seamless steel pipe and removing spirals in the country. The strategy supports the development of local businesses against foreign peers, creates jobs, cuts inventory and reduces shortage risk. Another strategy concerned the reuse of OCTG thread protection, which significantly reduced plastic waste and promotes efficient resource utilization.

Match inventory storage level with actual demands

to reduce inventory and appropriately utilize storage space. The technology based on machine learning was studied and developed, to forecast appropriate inventory levels for future demands.

Centralize inventory management through central database

to handle unused or lightly-used and reusable items. These items are returned to the central warehouse. This reduces new orders as well as procurement process and time, which hence results in lower expenses and production cost.

Evaluate, test and write off inventory

which are degraded, obsolete or inconsistent with current operations. The process is to increase storage efficiency and reduces storage cost.

Green Logistics Management

PTTEP operates logistics according to the 3E strategy (Economics, Efficiency and Environment) and aligns the operations with Safety, Security, Health and Environment (SSHE) standards. In focus are also effective cost management, planning, forecasting, collection, international standard shipments, and reliability in the delivery process. The Company has installed the GPS vessel monitoring system in every ship since 2013 to ensure efficient use of fuel. The company controls fuel consumption and reduces green gas emissions simultaneously as well as implements the Centralized Vessel Utilization Management system.